Zero pesticide cases thanks to purely organic cocoa factory

PRONATEC is 100% organic and has implemented strict cocoa bean analysis procedures

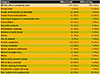

Winterthur, September 2023 – The family-owned Swis company PRONATEC has been processing cocoa beans into cocoa mass, butter and powder at its own exclusively organic plant since June 2022. An assessment carried out in September 2023 now shows there have been no pesticide cases in the semi-finished cocoa products since production started. According to PRONATEC, this is primarily due to the fact that the company’s new plant is purel organic so that any mixing with conventional products can be completely ruled out. Another contributing factor has been the strict cocoa bean analysis procedures developed by PRONATEC. These allow the company to detect even raw materials with minimal traces of residues with utmost reliability and exclude them from the production process. In the cocoa processing industry, organic and conventional products are usually processed on the same production line, which can lead to mixing and induce high follow-up costs.

During this first year of production, all products of PRONATEC Swiss Cocoa Production were subjected to extensive testing. An evaluation carried out in September now confirms the advantages of the exclusively organic production plant: There have been no pesticide cases detected in the products the company has processed itself since production started. This is despite the fact that the volume of beans processed has increased by around 80% over the same period. "The fact that we have not had a single pesticide case validates our decision to go for a purely organic plant," says the delighted CEO and company owner, David Yersin. "There is no mixing with conventional products here. Now people can see the benefits in black and white." So far, PRONATEC Swiss Cocoa Production has produced approximately 7000 tons of organic semi-finished cocoa products.

Extremely meticulous analysis of the cocoa beans and a specially developed analytical procedure have contributed to this outstanding result. "Many processors have the problem that their pesticide analysis of the raw materials does not match the analysis of the processed products," explains Samuel Hanimann, Head of Quality Management. "Problematic raw materials are not reliably detected and lead to significantly higher follow-on costs, if the residues are only detected at the semi-finished product stage. PRONATEC has developed a process that produces very accurate and representative results and this is reflected in higher product quality." The representative analysis also ensures that the limit values for heavy metals such as cadmium in chocolate and cocoa products are not exceeded.

Because it has its own subsidiary company in the Dominican Republic, which is the source of most of the cocoa beans it processes, PRONATEC has been able over the past few years to optimise the quality of the cocoa beans and prevent any mixing with conventional raw materials. From procuring the beans from small-scale farmers, through fermentation and export to processing and sale of the finished product, all stages of the process are in PRONATECÂ’s own hands.

From 2024, PRONATEC's cocoa products will also be available with the US Regenerative Organic Certified® ROC uses internationally recognised organic labels as a baseline. From there, it adds important requirements for soil health, animal welfare and fair terms for farmers.